Shri sabhari smelters Private Limited

Eco Friendly Recycling

We practice fairness and trust in all our dealings and demonstrate respect through our actions. We are extremely proud of our team of professionals who are both committed to delivery of high results.

About Us

Shri Sabhari Smelters Private Limited is a rapidly growing organization, with a state-of-the-art Lead Processing Unit in Chennai, Tamil Nadu, India.

Shri Sabhari Smelters Private Limited was established in the year 2007. The company is dedicated to Lead & Lead Products with environment friendly processes.

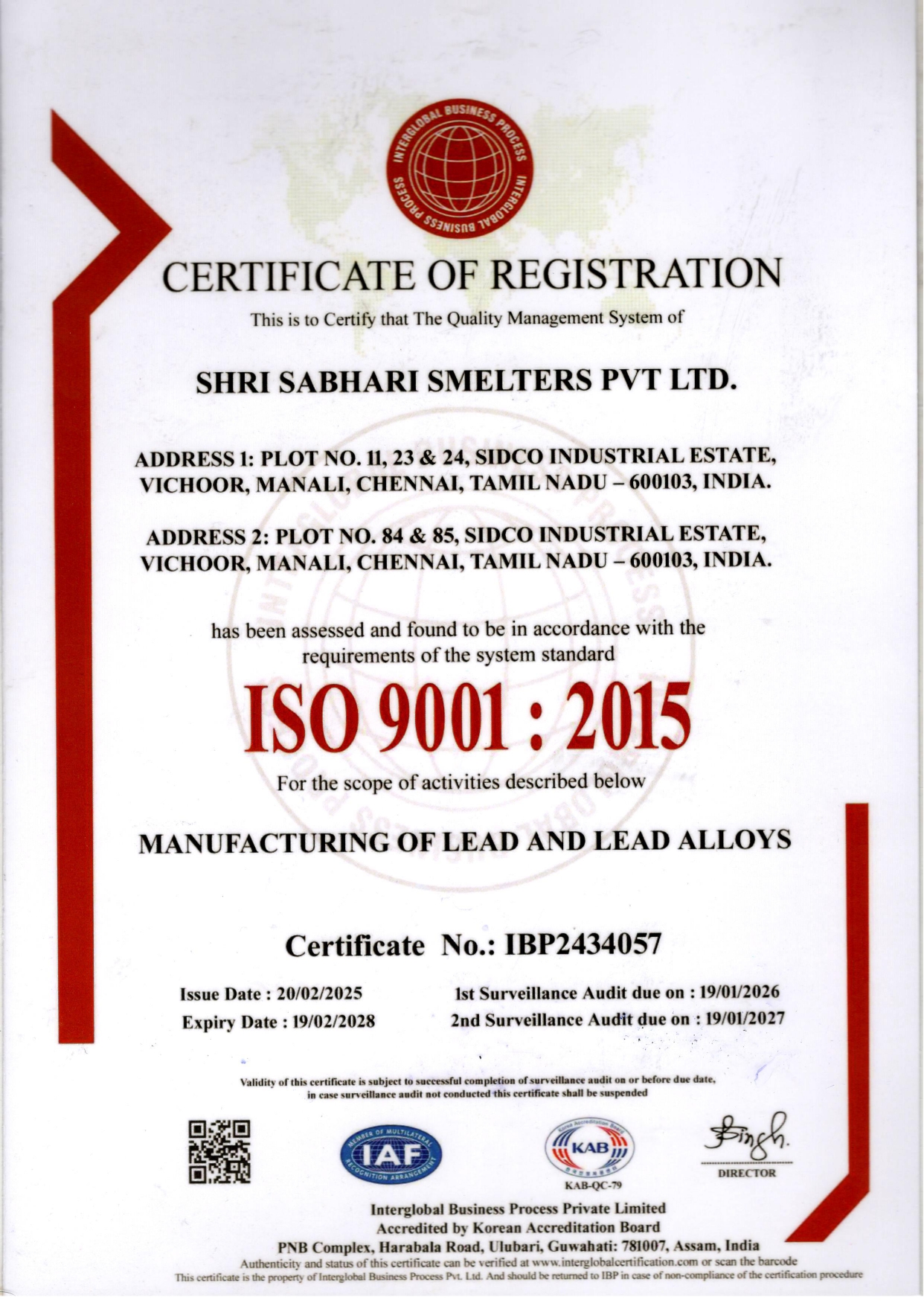

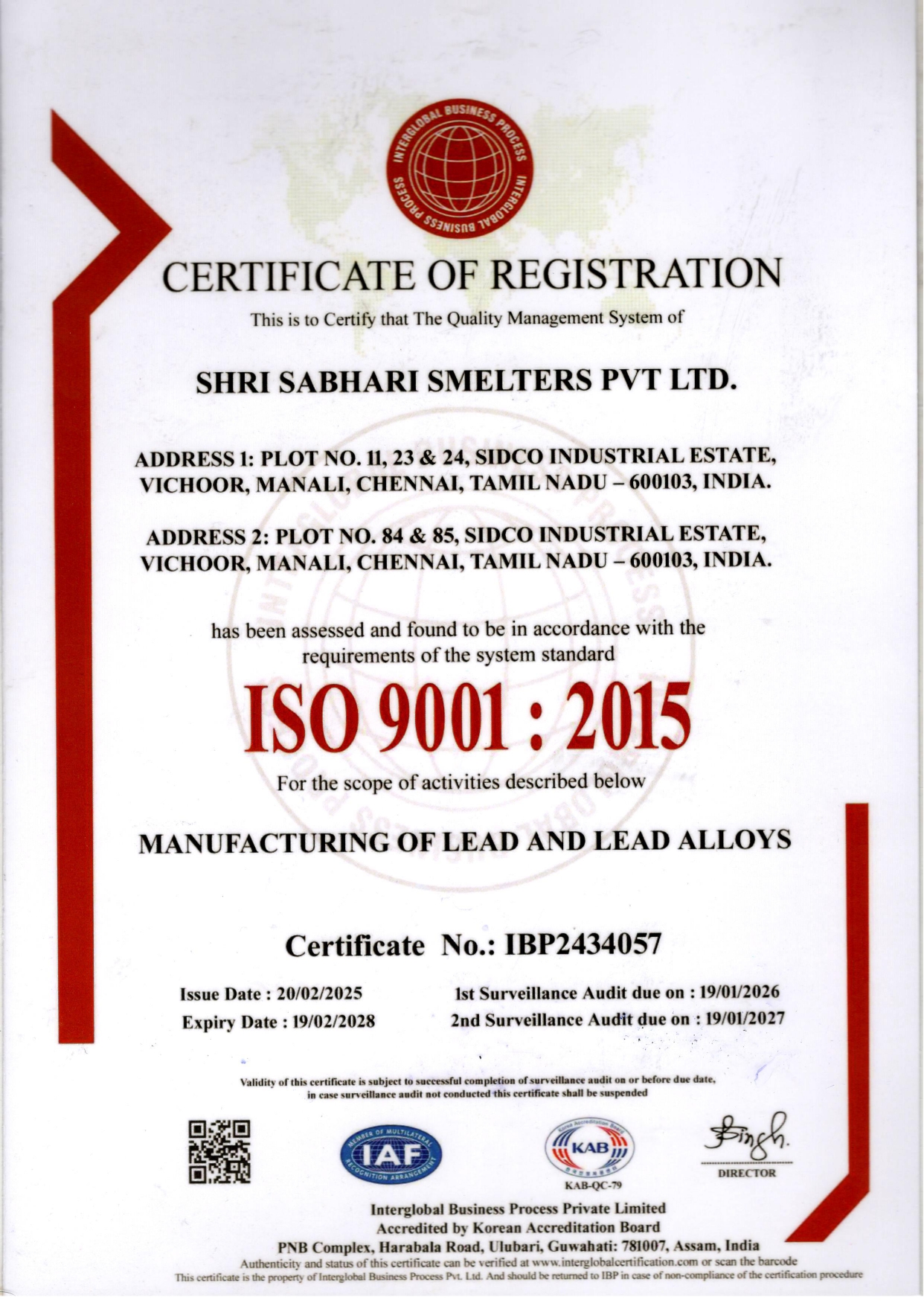

We manufacture Lead Metal by the process of Smelting and Recycling followed by Refining, Alloying and the manufacture of Pure Lead. We have obtained ISO 9001:2015 Quality Management System Certification from AGQR and conform strictly to ISO - 8000 guidelines.

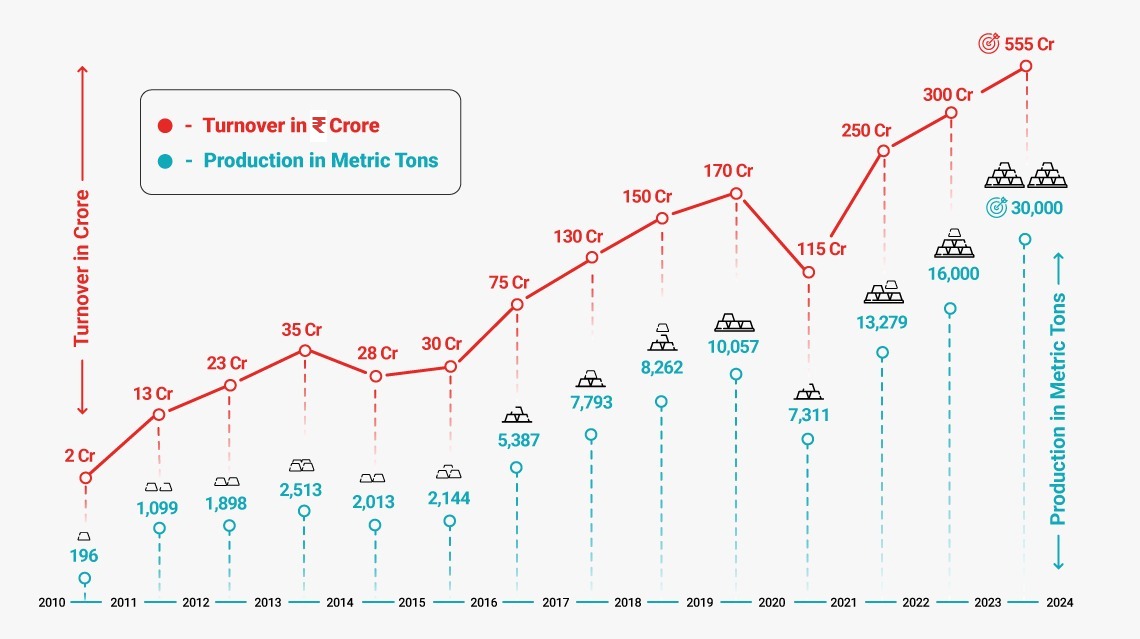

Growth Chart

About Us

Shri Sabhari Smelters Pvt ltd is a rapidly growing organization, with a state-of-the-art lead processing unit at Chennai, Tamil Nadu, India.

Shri Sabhari Smelters Pvt ltd was established in the year 2007. The company is dedicated to lead & lead products with environment friendly processes.

We manufacture lead metal by the process of smelting and recycling followed by refining, alloying and manufacture of Pure Lead. We have obtained ISO 9001:2008 Quality Management System certification from AGQR and conform very strictly to ISO - 8000 guidelines.

We Are Here to Increase Your Knowledge With Experience

Since establishing Shri Sabhari Smelters Private Limited, we have constantly engaged in raising the bar with every milestone achieved.. We have gradually emerged as a leading and prominent name in the Lead Recycling business segment, both in the Local and International market. Along with our employees, we stay committed to a shared set of values like Courage, Achievement, Respect, Responsibility, Integrity, and Transparency. We owe our success to our valued customers and well-wishers who inspire us to grow and innovate.

Mr. R. Saravana Kumar

Managing Director

Mr. R. Saravana Kumar, Managing Director

We Are Here to Increase Your Knowledge With Experience

Since establishing Shri Sabhari Smelters Private Limited, we have constantly engaged in raising the bar with every milestone achieved.. We have gradually emerged as a leading and prominent name in the Lead Recycling business segment, both in the Local and International market. Along with our employees, we stay committed to a shared set of values like Courage, Achievement, Respect, Responsibility, Integrity, and Transparency. We owe our success to our valued customers and well-wishers who inspire us to grow and innovate.

Value That Are Kept About us

3,000 Metric

Tons Production

Rotary Furnace

Refining and Alloying Pot

Spectrolab Spectrometer from Germany for Metal analysis

Our Priorities

Committed To Delivering of High Standard Results

Since inception, we have worked towards continuous development and incorporating sustainable practices in everything we do. Our company is a unique combination of a strong technical team, committed professionals, and a dedicated workforce. We are led by a common vision to provide specialized services to various vital business sectors using innovative strategies. Customer satisfaction is at the heart of our organisational culture and is the success formula that gives us the winning edge.

- Advanced manufacturing Facilities

- Quality Control

- Employee Safety & Skill Development

- ECO Friendly

At Shri Sabhari Smelters Private Limited, the solutions we offer are flexible and are customised to the dynamic requirements of our clients. Our Production Unit runs at optimum capacity of 36,000 metric tonnes per annum and we deliver high-quality, cost-effective products at unbeatable turnaround times. Thanks to the latest technology. Our Manufacturing Unit is equipped with Automated Battery Crusher, Smelting Rotary Furnace and Alloying Pot.

Our manufacturing capabilities and the production unit conform to all norms set by State and Central Government Pollution Control Boards. Care has been taken to lessen the carbon footprint and to be more environment friendly.

We have constantly nurtured our R&D and Quality Control departments as they play a significant role at every stage of manufacturing. These departments are also key to designing customized solutions for client. We are equipped with an Avant advanced grade OES (Optical Emission Spectra) – Spectrophotometer from Germany and a wet chemistry laboratory. These labs and the R&D Unit, along with our integrated quality management system are continuously engaged in product quality enhancement. From raw material procurement to product finish, thorough quality checks ensure only best-in-class products leave the manufacturing unit.

A rigorous quality control policy is in place, and we are committed to operating our company that conforms to the International Standard ISO 9001:2015, planned and developed jointly with our other management functions. This has helped us upgrade ourselves in both technology & industry knowledge.

At Shri Sabhari Smelters, employee safety is backed by a robust safety program that protects our workforce, property, and the public from any untoward incidents. Employees at every level, including management, are responsible and accountable for the company’s overall safety initiatives. Our workforce exhibits complete and active participation every day, in every job at the worksite. The Management upholds and supports the safety programs with necessary equipment, training, and procedures.

Skill Development helps our workforce to stay motivated and remain on top of their game. Our training modules include soft skills and technical training: Sales Management | Marketing Performance Management | Leadership Development | Personal Skill Development | Emotional Intelligence | Effective Communication | Business Etiquette | Time Mastery, Presentation Skills | Personal Effectiveness | Interpersonal Skills Work Life Balance | Collaboration | Mentoring | Workplace Ethics |Driver/Chauffeur Training

Shri Sabhari Smelters puts sustainability, environmental concerns, and safety at the forefront of its operations. We understand and acknowledge our responsibility towards creating a greener and safer planet. We are constantly exploring ways and taking possible measures to conserve our environment and avert pollution at every stage of production. We have put in a lot of effort to create natural ecosystems in and around our manufacturing unit. With our experience, best practices and the determination of our management and employees, we are affirmative that our company is headed towards a sustainable growth.

Our Priorities

At Shri Sabhari Smelters Private Limited, the solutions we offer are flexible and are customised to the dynamic requirements of our clients. Our Production Unit runs at optimum capacity of 36,000 metric tonnes per annum and we deliver high-quality, cost-effective products at unbeatable turnaround times. Thanks to the latest technology. Our Manufacturing Unit is equipped with Automated Battery Crusher, Smelting Rotary Furnace and Alloying Pot.

Our manufacturing capabilities and the production unit conform to all norms set by State and Central Government Pollution Control Boards. Care has been taken to lessen the carbon footprint and to be more environment friendly.

We have constantly nurtured our R&D and Quality Control departments as they play a significant role at every stage of manufacturing. These departments are also key to designing customized solutions for client. We are equipped with an Avant advanced grade OES (Optical Emission Spectra) – Spectrophotometer from Germany and a wet chemistry laboratory. These labs and the R&D Unit, along with our integrated quality management system are continuously engaged in product quality enhancement. From raw material procurement to product finish, thorough quality checks ensure only best-in-class products leave the manufacturing unit.

A rigorous quality control policy is in place, and we are committed to operating our company that conforms to the International Standard ISO 9001:2015, planned and developed jointly with our other management functions. This has helped us upgrade ourselves in both technology & industry knowledge.

At Shri Sabhari Smelters, employee safety is backed by a robust safety program that protects our workforce, property, and the public from any untoward incidents. Employees at every level, including management, are responsible and accountable for the company’s overall safety initiatives. Our workforce exhibits complete and active participation every day, in every job at the worksite. The Management upholds and supports the safety programs with necessary equipment, training, and procedures.

Skill Development helps our workforce to stay motivated and remain on top of their game. Our training modules include soft skills and technical training: Sales Management | Marketing Performance Management | Leadership Development | Personal Skill Development | Emotional Intelligence | Effective Communication | Business Etiquette | Time Mastery, Presentation Skills | Personal Effectiveness | Interpersonal Skills Work Life Balance | Collaboration | Mentoring | Workplace Ethics |Driver/Chauffeur Training

Shri Sabhari Smelters puts sustainability, environmental concerns, and safety at the forefront of its operations. We understand and acknowledge our responsibility towards creating a greener and safer planet. We are constantly exploring ways and taking possible measures to conserve our environment and avert pollution at every stage of production. We have put in a lot of effort to create natural ecosystems in and around our manufacturing unit. With our experience, best practices and the determination of our management and employees, we are affirmative that our company is headed towards a sustainable growth.

Portfolio

Our Certificates

- ISO 9001:2015

- BMR Certificate

- AEO

Our Certificates

- BMR Certificate

- SILMA0005

- ISO 9001:2015

- AEO